Find Non Ferrous Silicon Carbide, Copper Grinding Silicon Carbide, Refrastoriness Silicon Carbide on Industry Directory, Reliable Manufacturer/Supplier/Factory from China.

New Products

| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CFR,CIF |

| Min. Order: | 1 Ton |

| Delivery Time: | 15 Days |

Model No.: 88%SiC

1.Product Introduction

It is a high quality Refractory material and widely used in metallurgy, energy and chemical industries.As different binding material, SIC's performance, working condition and life are all different. In silicon carbide refractories, clay is the most common, the lowest price and the most simple process.At present, in China's ceramic industry, clay is used in a large amount of silicon carbide kiln. Aluminum, oxygen and silicon carbide in the clay react in 1120 ~ 1150 ℃,The clay amount in the product is generally not more than 15%, the fine powder in the ingredients should not be too much, otherwise it is easy to oxidize.The content of silicon carbide is between 50% and 93%.It is used to make saggar, padded and NC-G.

2.Product Application

Silicon carbide used for 3-12 inch monocrystalline silicon, polycrystalline silicon, potassium arsenide, quartz crystal wire cutting. Solar photovoltaic industry, semiconductor industry, piezoelectric crystal industry, engineering materials.Silicon carbide for semiconductor, lightning rod, circuit components, high temperature applications, UV detectors, structural materials, astronomy, disc brakes, clutch, diesel particulate filter, filament pyrometer, ceramic film, cutting tools, heating elements , Nuclear fuel, jewelry, steel, protective gear, catalyst support and other fields.

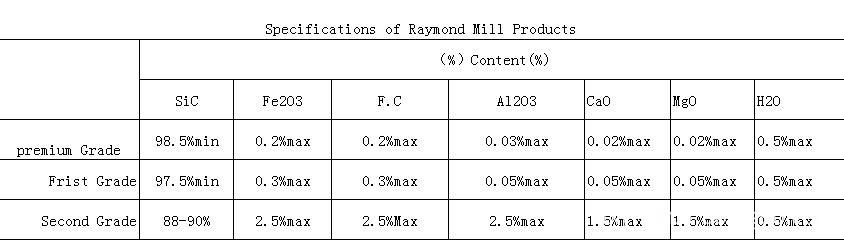

3.Product Index

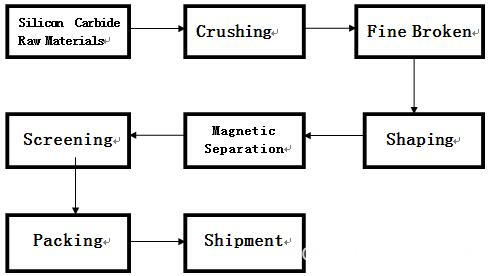

4.Product process

The anthracite quartz sand and other mineral raw materials processed into pieces, and then broken, the initial crushing, after fine broken, plastic, magnetic separation, screening after the silicon carbide products have been obtained, the final package can be shipped

5.Packing And Transportion

Woven bag, lined with plastic film bags, each 25kg can also be packaged according to customer demand.

Transportation and handling: During the transportation process, the silicon carbide shall not be dragged with hook, should prevent mixing with hard materials. It should belight unloading to reduce packaging crushing.

Storage: The silicon carbide should be stored in a cool and dry place, to prevent rupture of bags, to prevent moisture and other substances to affect the product. Storage should away from sources of pollution.

Product Categories : Silicon Carbide