(1) Processing form of graphite material There are three main types of graphite electrode processing: pressurized vibration method, numerical control automatic forming method and mechanical processing method. (1) Pressurized vibration method: The pressurized vibration method requires a special Machine Tool, and the electrode master mold has the opposite shape to the electrode. The graphite material and the forming Tool are placed relative to each other during processing, leaving a certain gap. The machining fluid, which is a mixture of water and Abrasives, is injected into it. While passing the machining fluid, the graphite and the forming tool are ultrasonically vibrated. Under the action of the Abrasive impact force, the graphite is slightly exfoliated into the required shape. The abrasive is SiC, B4C or diamond. The coarser the abrasive, the faster the processing speed. When the machine is working, it adopts the sealed type and water curtain type for processing. It is suitable for EDM forming in mass production.

(2) Numerical control automatic forming method: The numerical control automatic forming method requires a dedicated graphite electrode forming machine, which adopts the numerical control method, has an automatic tool exchange device, and can accommodate multiple tools. In order to improve the processing environment, the graphite electrode is surrounded by a water curtain to prevent the graphite dust from dispersing. In addition, the wet machining method can also be used to prevent tool wear and graphite dust from scattering by water-soluble cutting fluid. The machine tool has a high-performance filter device, which can separate the cutting fluid and graphite chips, and can ensure continuous processing for a long time. It is an ideal special equipment for graphite electrode processing and is suitable for electrode processing for molds. However, its price is relatively high, and its application in China is not yet widespread. (3) Mechanical processing method: The mechanical processing method is the main method adopted by the general domestic mold production units. Graphite materials can be processed by turning, milling, drilling and grinding methods. In addition, graphite materials are prone to fly ash during mechanical processing, which will adversely affect processing equipment and operators. Contact us if you need more details on High-quality Ultra-high Graphite Electrode. We are ready to answer your questions on packaging, logistics, certification or any other aspects about High-quality Ultra-pure Graphite Electrode、High-quality Ultra-high Power Graphite Electrode. If these products fail to match your need, please contact us and we would like to provide relevant information.

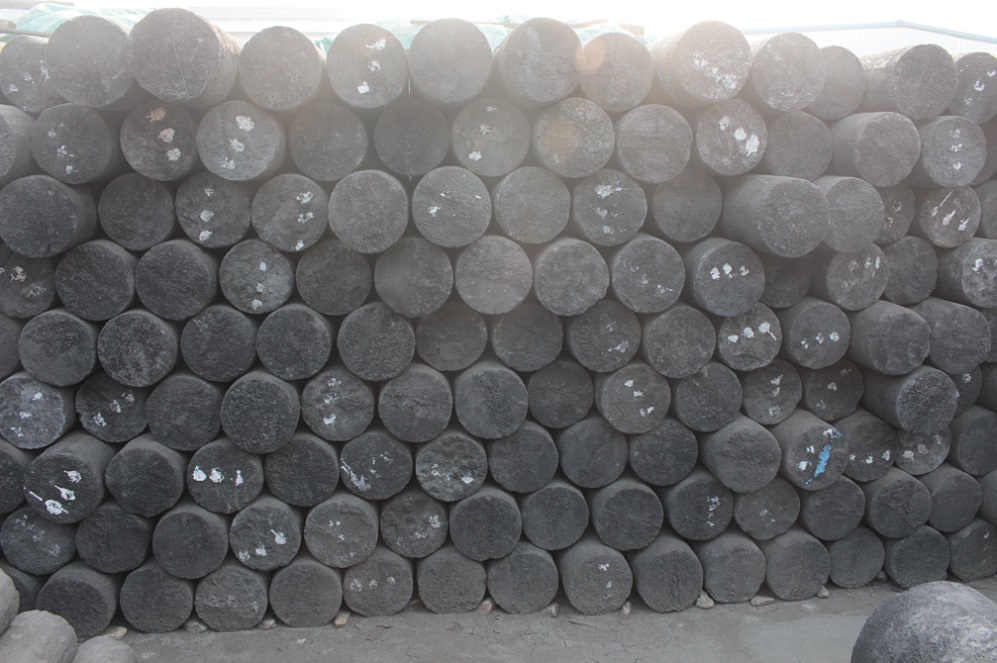

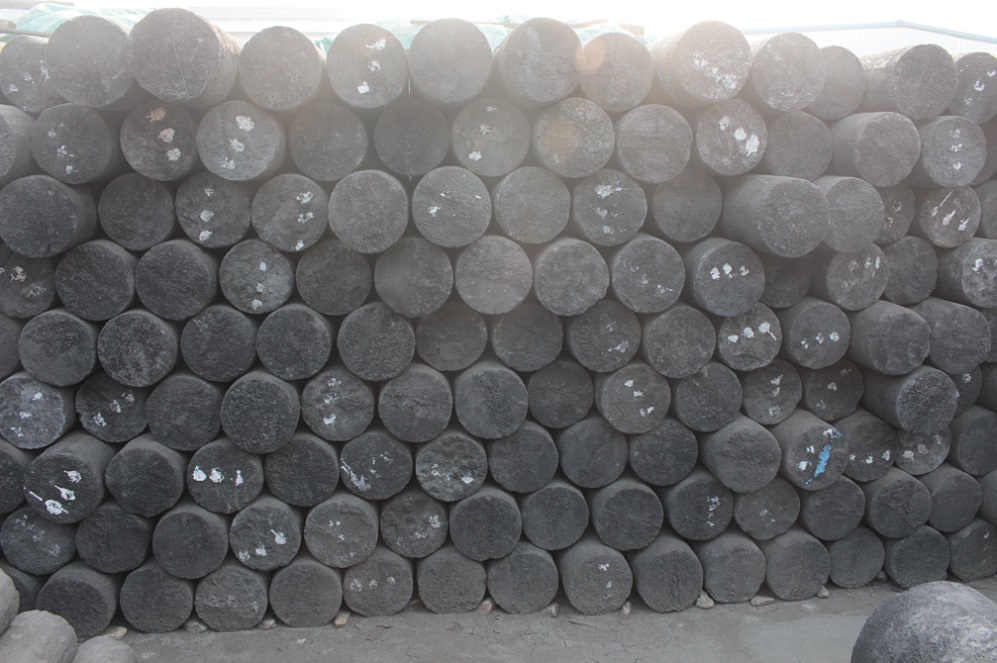

Product Categories : Graphite Electrode > Ultra High Power Graphite Electrode